Where is your business on the supply chain maturity chart?

Find out where your business is on the supply chain maturity curve. Discover how you can move up it and improve your business KPIs and efficiency.

Manufacture and wholesalers wanting to develop real business intelligence, need to understand their current level of supply chain maturity so that they can improve their resilience and bolster long-term performance.

The supply chain maturity curve is a separate concept from the adoption curve. It attempts to measure supply chain robustness by looking at what might happen if any particular link failed. Immature supply chains have a habit of crumbling when there is a problem with any component in the system. By contrast, robust supply chains are those that adapt to changing circumstances and even accommodate operational failures.

The purpose of this article is to introduce you to different supply chain maturity stages so that you can determine where your business currently lies and how you might improve if necessary. Having this conversation is crucial because it helps you characterize your capacity for change management while also showing you precisely how you can to enhance your current approach.

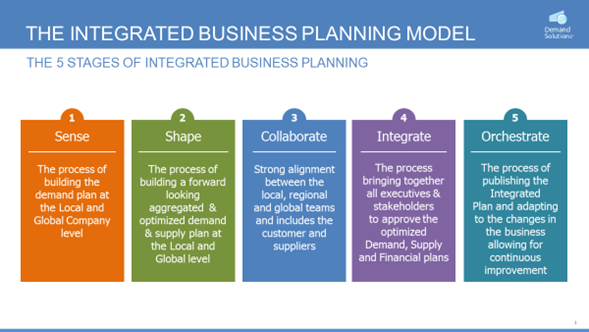

The Five Stages Of Supply Chain Maturity

Demand Planning characterizes five qualitatively distinct stages of supply chain maturity. Each of these represents a step-change in sophistication, adaptability, and resilience.

Stage One: Sense

The “sense” stage of the supply chain maturity curve is the most basic and involves building a static plan at the local and global company levels. Businesses at stage one are often just working off a single user interface (such as a spreadsheet) and building demand forecasts using historic sales averages.

In a world without sudden supply chain shocks, this approach might suffice. However, future demand is not conditional on past sales in most markets, making this a brittle forecasting tool at best.

Stage Two: Shape

Stage two of supply chain maturity is when your company uses methods to forecast future input needs and requirements using forward-looking data. For example, a business at this level might apply spreadsheet data to material requirements planning (MRP) software for computer-based inventory management and scheduling.

Companies that adopt this method can match their demand to supply capabilities, converting lists of requirements for raw materials, component parts, and subassemblies into a final established schedule.

Stage Three: Collaborate

Stages one and two both operate internally to the company, providing local intelligence. However, businesses at stage three – the collaboration stage – attempt to introduce industry-wide intelligence to their supply chain operations.

The first step of collaborating involves sharing forecast information with customers so they can offer their insights to improve and enrich supply chain management. The second is taking these learnings and sharing them with suppliers, creating a kind of network intelligence, both up and down the chain.

Part of this process involves conducting various “what if” scenarios, laying out contingency plans for what might be around the corner. For instance, you might model what could happen if a new competitor entered the market or governments imposed trade barriers and restrictions on imported and exported goods.

Stage Four: Integrate

Businesses at the integration stage of supply chain maturity can involve more stakeholders and sources of information in their planning, creating a kind of “big tent.” Companies at this stage have clear sales and operations planning (S&OP) in place. They have adopted a regular integrated business management process that allows leadership to evaluate key aspects of the supply chain. These could including things like:

- New product introductions

- Inventory management

- Demand management

- Sales and marketing

- Financial reconciliation

- Product reviews

- Demand reviews and appraisals

Practically speaking, supply chain managers and senior business leaders at this stage hold meetings – typically monthly – checking cash flow can support meeting the demand from the market. They also use it to review the accuracy of existing forecasting methods and improve them if necessary.

Stage Five: Orchestrate

Organizations at the orchestrate stage integrate their plans and publish them to the rest of the enterprise while simultaneously providing methods to measure and improve on them. In simple terms, firms at this level can adapt to changes in the operating environment using intelligence signals they receive through their sensor network. Hence, you can think of the orchestration stage as making integration “real-time,” allowing for on-the-fly adjustments.

Sensors data acquired from electronic data interchange (EDI) could include signals from:

- Social media

- Ecommerce platforms (such as Amazon)

- Shop floor data on machining and production

- Shared supplier data

- Ancillary and broader economy data

The goal here is to transition to what experts in the field sometimes call Multi-Echelon Inventory Optimization or MEIO. This concept aims to integrate information from across the supply chain to determine what actions each business should take in the context of the inventory position of all the others. Importantly, it avoids the traditional sequential way of doing things (where companies merely react to inventory shocks coming from other parts of the chain) and instead tries to get the whole edifice working together as a single, unified organism. Firms at this stage use inventory optimization models combined with multi-echelon planning with their partners. The result is supply chain positioning models that characterize resource requirements at various production stages in real-time.

How do you eat an elephant? One bite at a time…

Once you establish where your organization sits on the supply chain maturity curve, the next step is to determine how much change your business can handle today.

Ideally, businesses at stage one would move to stage five in a single step. In theory, doing so would have a more profound impact on their ability to meet customer expectations than adopting a process of continuous improvement through time. However, in practice, there are conditions they must satisfy first because they can make the jump.

Most commentators describe S&OP as a journey – something your business gravitates towards over the long-haul. The reasons for this are generally organizational, not technological. Certain conditions need to be in place first.

While you would ideally like to move from your current stage to stage five in a single leap, most companies find it easier to walk before they can run. Often, this means doing the groundwork first and getting buy-in from the whole team. It also means putting in place integrated software solutions capable of delivering the required functionality. Spreadsheets simply won’t suffice.

Before pushing ahead with change, ask yourself the following questions:

- Do you have buy-in from the board?

- Is the required engagement happening across the business?

- Do you have the technology available to achieve the data analysis required?

- Is your data in a usable state – or does it need to be cleaned? For example, can you segment, slice, and dice your sales history against many different characteristics to gain insights into customer and product behavior from the data you have?

- Can you measure the KPIs with the data you have?

- Can you eliminate unnecessary manual work within the process?

Companies that successfully adopt S&OP typically achieve several core competencies that make their supply chain operations more resilient.

The first is the ability to segment demand based on granular product, customer, and channel characteristics. Firms that can better diagnose the sources of perturbations in their supply chains, can better mount targeted and intelligent responses.

The second is the ability to take profit and loss criteria into the supply chain management process. For these firms, decisions not only respond to operational objectives, (such as allocating inputs or managing inventory) but also calculate the ramifications on financial performance too.

The third is the capacity to distill multiple data streams into a single, unified forecast that executives and other stakeholders can use to make informed decisions. Organizations with this capability have better visibility over the movement of resources and can better model likely future scenarios in their “what if” analysis.

The fourth and final competency is the ability to react to changes in demand that arise from the company’s own actions. Mature supply chain management involves, for instance, being able to predict how marketing campaigns by the firm (and perhaps others) will affect overall resources and inventory requirements.

Achieving the “orchestration” stage on the supply chain maturity chart offers a host of benefits for your business. Individual inventory managers gain more control over the quantity of stock they should order or have available at any given time. Marketing managers feel more confident in managing the changes in the supply chain that result from their campaigns. And partners become more integrated with your processes, allowing everyone to economize and make better use of resources.

Are you currently stuck in one of the lower stages on the supply chain maturity chart?

If so, we can identify where you now stand and then carry out an economic impact assessment, showing you the costs and benefits of moving your enterprise to the next stage. With advances in technology and S&OP, no organization has to make do with dumb planning or single-user spreadsheet interfaces. A more integrated and intelligent approach could lead to vast improvements in your KPIs. Click here to get started: https://www.demandsolutionseurope.com/contact-us/